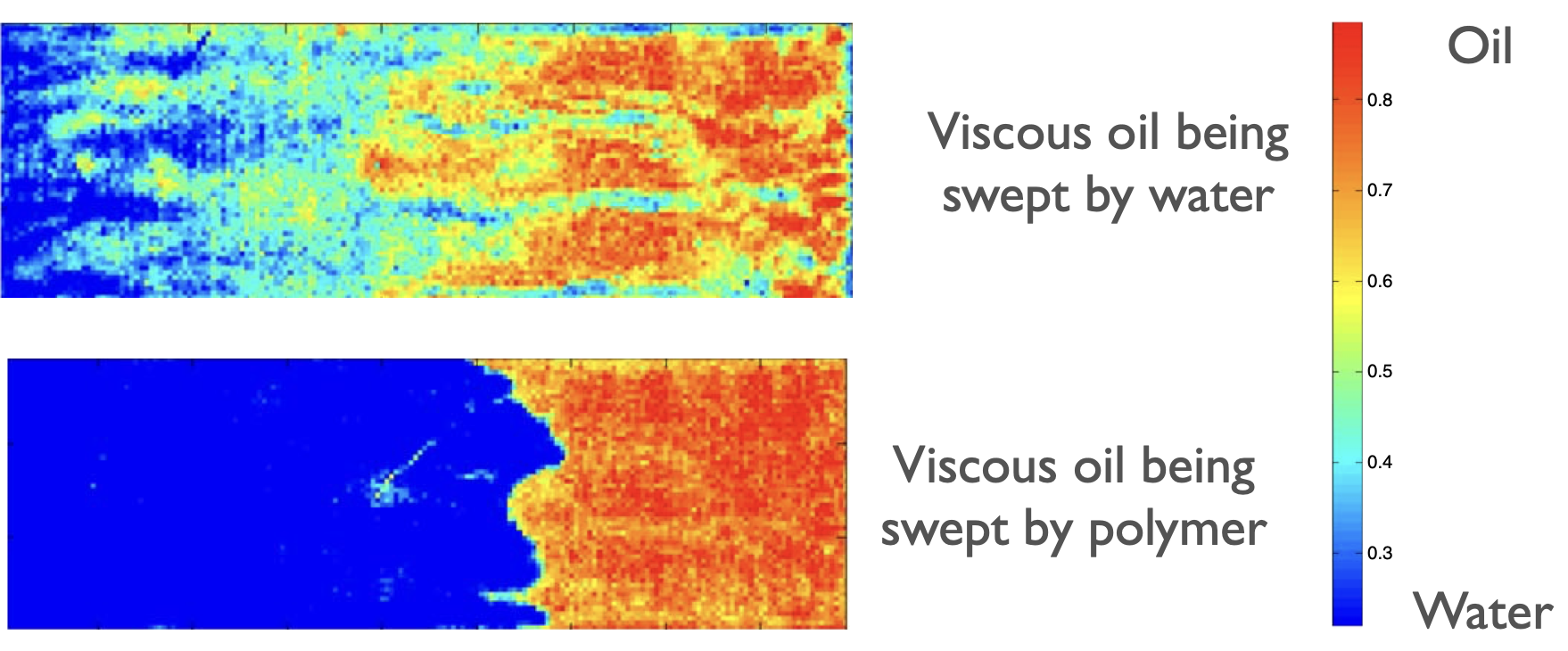

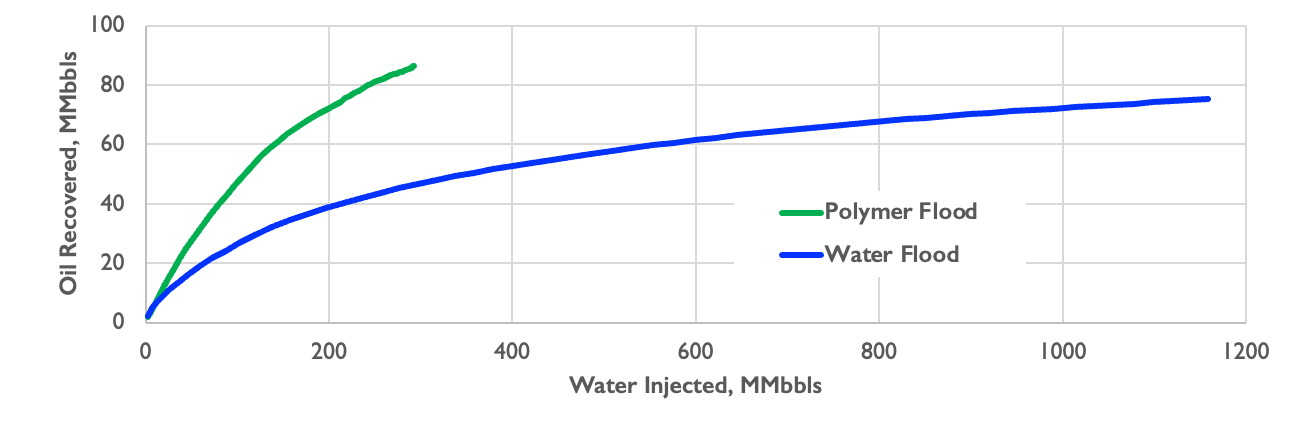

Polymer flooding works by changing the mobility ratio between the oil in the reservoir and the water that is injected. Only a small amount of polymer (c. 0.25%) is added to the injection water to increase the water viscosity (from about 1cP to 25cP). The viscosified water can then sweep the oil with a more stable flood front towards producing wells, accelerating production and increasing recovery.

The mobility ratio depends upon the ratio between the fluid viscosities and the ratio of oil and water relative permeabilities at the fluid interface. If the mobility ratio is high, because the oil is less mobile, the water fingers through the oil, bypassing much of the oil in place, and potentially leaving the bypassed oil unrecovered. If the oil and the water are equally mobile the water can sweep the oil from the reservoir in a very efficient piston-like fashion